Hydraulic cylinders installed in hydropower plants place special demands on documented quality

Hydropower suppliers demand reliable hydraulic cylinders that can handle working under challenging conditions in a harsh environment

Challenging working conditions without breakdowns.

As a supply company, a hydropower plant must have continuous operations A vital energy supply, like a hydropower plant, must have continuous operations without unplanned interruptions.

This places considerable demands on all components, here the hydraulic cylinders, often perform extremely vital functions in handling large masses of water, even under extremely harsh environmental impact! Something Fjero has extensive know how off and wide range of proven solutions for.

Components that match requirements

Significant environmental impact in daily operations includes corrosion, dirt, and ice on the piston rod. All of which, place huge demands on the correct choice of materials and components.

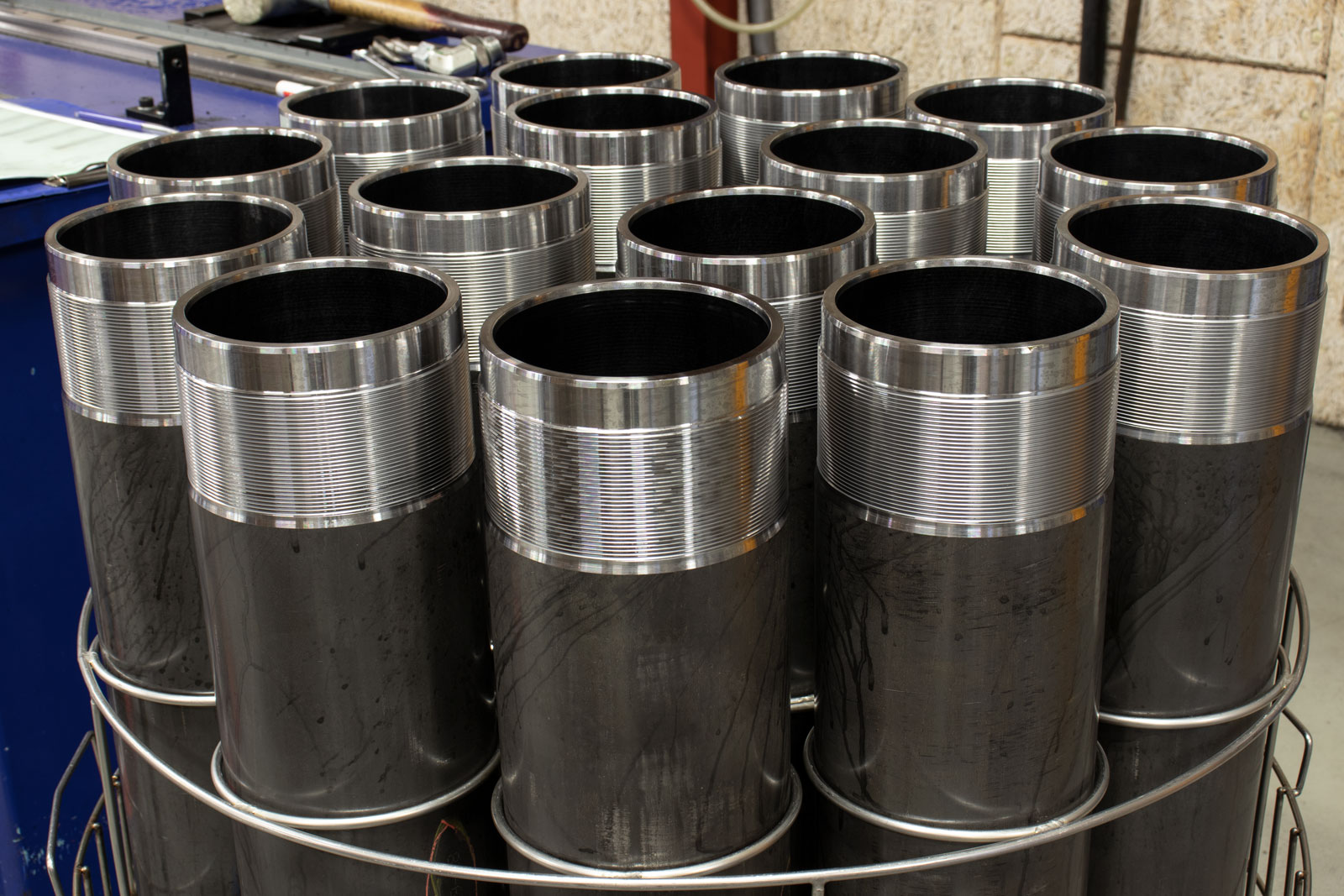

Applications often have long periods of inactivity making the environmental impact even harder, and places even greater demands on the design. At FJERO we base our designs for these challenging conditions, on our F1 cylinders, which have a high degree of traceability with documented quality through certificates and third-party approvals. If traceability is not required, we base the design on FJERO’s F2 cylinders. Based on components from the F1 and F2 cylinders, we adapt the design to the individual customer’s needs and wishes. FJERO’s hydraulic cylinders are designed for an optimal lifetime – even under difficult and demanding conditions.

Minimal maintenance

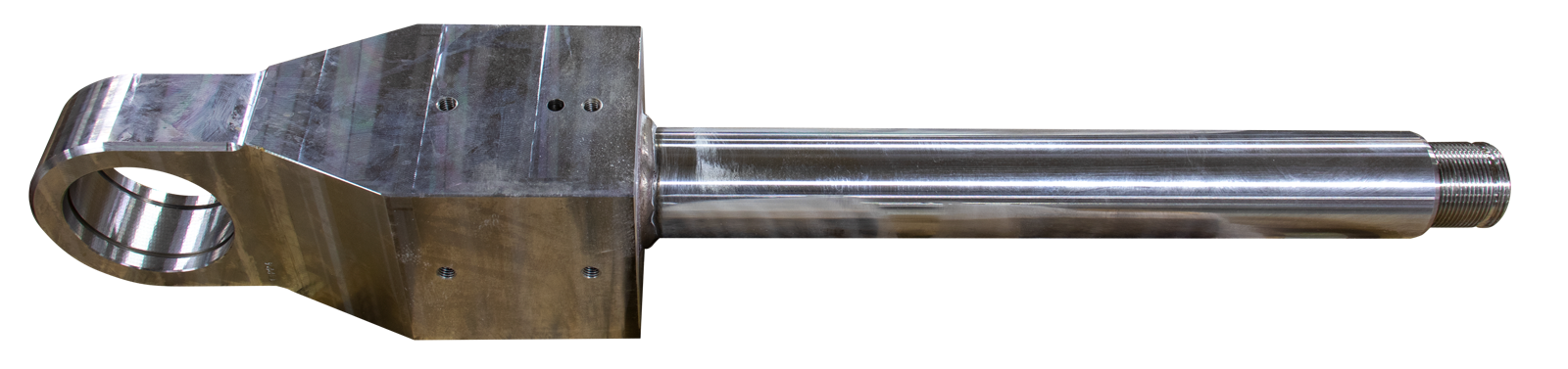

Service and maintenance are often challenging and must be minimised to ensure daily operations. This places significant demands on the hydraulic cylinders. FJERO always designs the optimal solution based on the customer’s special needs and requirements – and often also to the locked built-in dimensions according to which each hydropower plant is built.

We have an increased focus on selecting the optimal sealing systems, bearings and raw materials – all with a surface treatment that matches the requirements. With certified design, the customer is ensured the best solutions with high uptimes.

Flood Protection

Components to address the major future challenges of flooding

There is no doubt that the climate is changing. Increased and more intense rainfall, combined with stronger winds. Raises the demand for equipment to control water levels, both in inland waterways and from the sea. The design and durability of the components involved in these constructions, impose significant demands on manufacturers! As the installations are subjected to extreme stresses during severe weather conditions.

'

FJERO, leverages its extensive and long-standing experience from other demanding industries, to develop and construct solutions, that can protect people and infrastructure from flooding. In this way, FJERO A/S contributes strong hydraulic cylinders for flood protection.

Many fastening and combination possibilitie

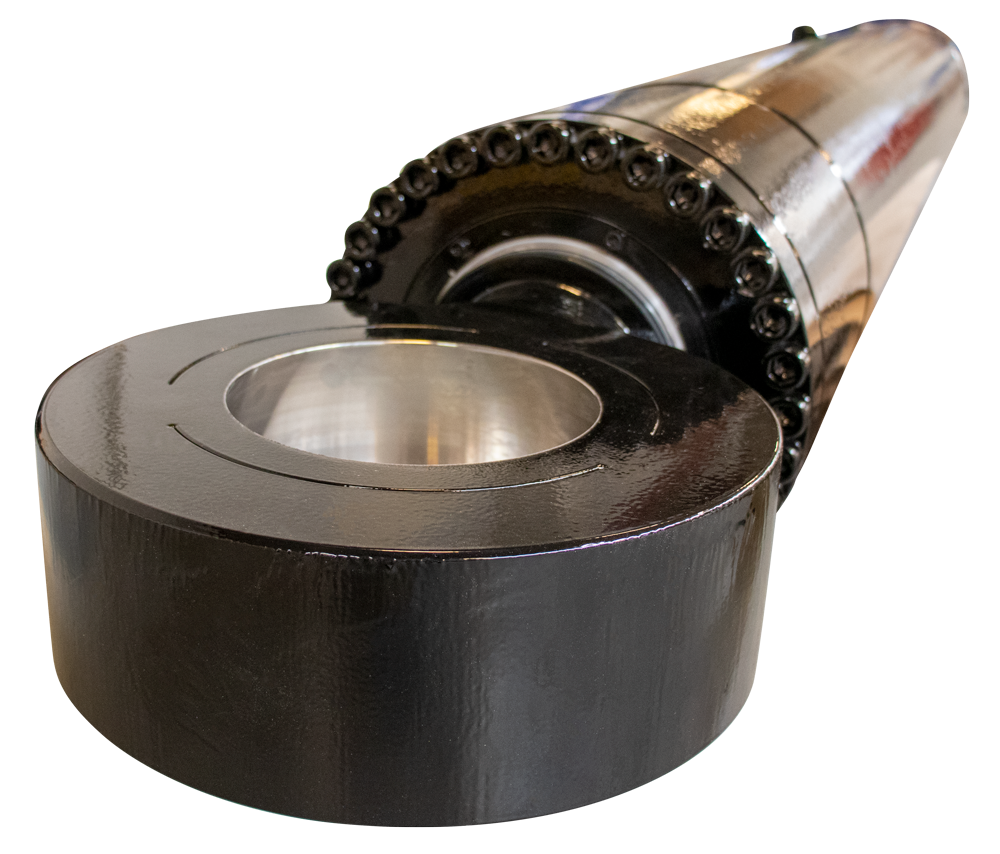

F1 and F2 cylinders are supplied with many fastening solutions, such as:

• Spherical bearing

• Spherical composite bearing

• Adjustable spherical composite bearing

• Trunnion

• Front flange

• Rear Flange

• Piston rod flange

• Clevis

• Fixed eye

• Fixed eye with bronze liner

• Threaded rod end

• Special fastener according to the customer’s wishes

By combining the different fastenings, we can meet all your requirements.

Read more about the F1 cylinder with traceability >

Read more about the F2 cylinder without traceability >

Contact our sales team today to learn more about effective solutions for your applications.

Niels Storgaard Jensen

Sales Manager & Partner

nsj@fjero.com

+45 96 16 00 03

+45 23 23 60 50

Sergej P. S. Pedersen

Key Account Manager

spsp@fjero.com

+45 30 66 40 90

Sales

Generel contact

sales@fjero.com

+45 96 16 00 00